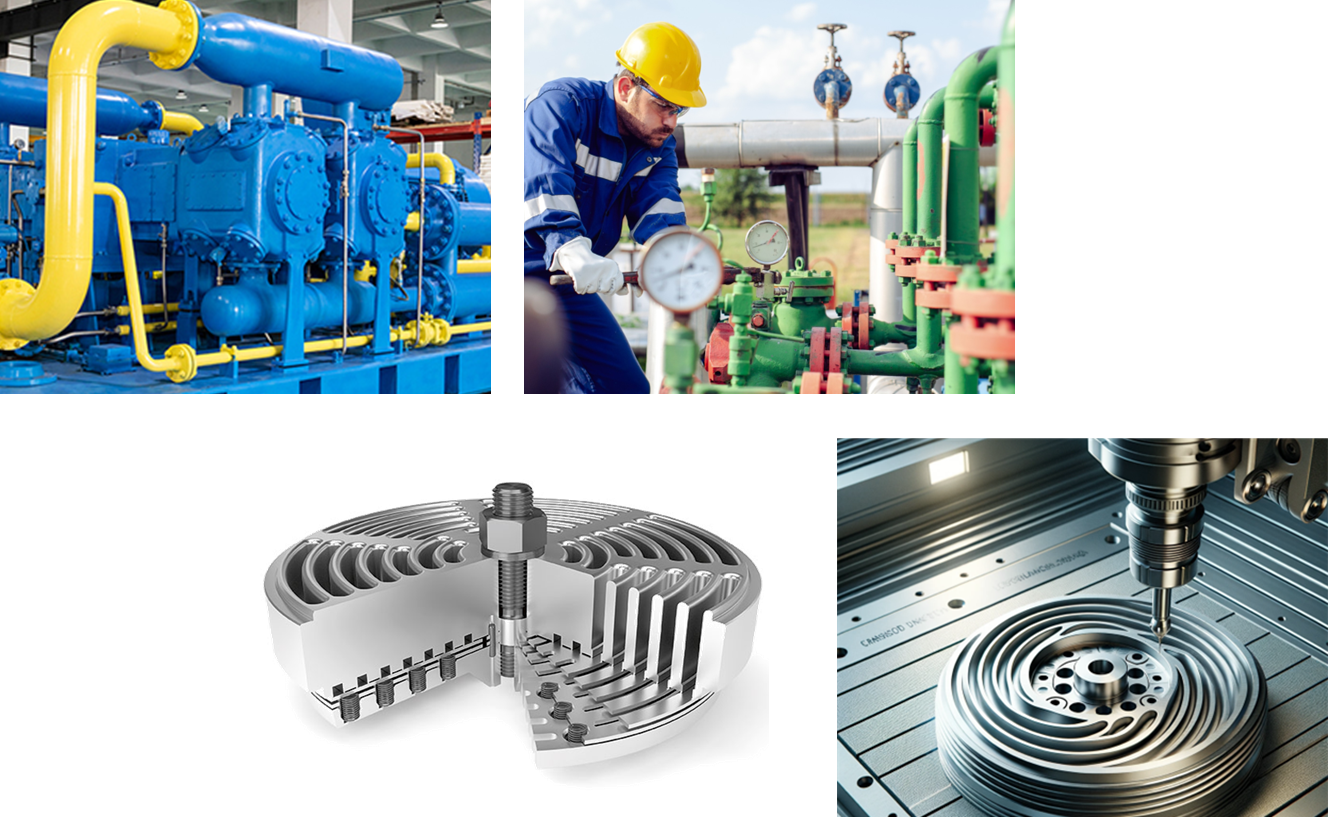

Our Manufacturing

Gas Compressor Valves

We pride ourselves on delivering exceptional components at unbeatable prices. With over two decades of industry experience, FEROZ TECH International has established itself as one of the leading innovators in the global compressor parts market. Our expertise ensures that every part we produce meets rigorous standards of durability and performance, driving efficiency and value for our customers.

Excellence in Compression Solutions

At the core of our mission, we empower our clients with unparalleled compressor valves and valve services, tailored to a broad spectrum of applications and compatible with any compressor brand. Our primary objective? To significantly reduce lifecycle costs and enhance the operational efficiency of reciprocating compressors.

- Retrofit/Reverse Engineering: We breathe new life into older systems, employing state-of-the-art reverse engineering to meet current standards and performance expectations.

- Reconditioning of Worn Parts: Our expert team meticulously restores worn components to their original glory, ensuring they deliver optimal performance and reliability.

- Repair of Damaged Components: We provide comprehensive repair services for damaged parts, employing precision and care to extend the life of your equipment.

- Parts Replacement for Any Compressor Brand: Our inventory is vast and versatile, offering high-quality replacement parts for any brand of compressor, ensuring you receive the right part at the right time.

- Upgrade/Optimization/Modification: Stay ahead of the curve with our upgrade and optimization services, designed to enhance your system’s efficiency and adaptability to evolving operational needs.

- Customized In-House and On-Site Training: Knowledge is power. We offer bespoke training programs, both at our facilities and on-site, to equip your team with the skills and insights needed for peak performance.

At FEROZ TECH International, we understand that the heart of your compressor’s performance lies in the valve.

It’s not just a component; it’s the cornerstone of reliability and quality in your operations.

Our Product Lineup

Our valve offerings are meticulously designed with both thermoplastic and steel internals to ensure unparalleled performance and durability. Our product lineup includes:

-

Plate Valves.

-

Concentric Valves.

-

Ring Valves.

-

Poppet Valves.

…and many others, each designed to surpass industry standards and enhance your compressor’s performance.

FEROZ TECH International offers a comprehensive inventory of superior valve assemblies tailored for both air and process gas compressors across various industries, including PET.

Engineered for excellence, our valves are designed to operate flawlessly in both high and low-pressure environments, accommodating a diverse range of applications and ensuring that your compressors run with unsurpassed efficiency and longevity.

Design

Our cutting-edge Research & Development laboratories stand at the forefront of this journey, propelling us to innovate and pioneer new materials and technologies. In partnership with you, we are dedicated to designing and manufacturing exceptional solutions that not only meet but anticipate the evolving demands of the market. Together, we set new standards, pushing the boundaries of what’s possible and shaping the future of our industry.

At FEROZ TECH International, our deep knowledge and specialized skills in these critical capacity control methods underline our commitment to delivering unparalleled efficiency and performance in reciprocating compressor operations.

Capacity Control Excellence

In the realm of reciprocating compressors, the art of capacity control is mastered through various sophisticated technologies. These include Bypass Control, Speed Control, Valve Unloading (both Stepwise and Stepless), Clearance Pockets, and Suction Pressure Reduction. At FEROZ TECH International, we pride ourselves on our expertise across all these capacity control systems, ensuring that we can tailor the most efficient solution for your specific needs.

Among the myriad of options, one stands out for its prevalence and effectiveness:

- Conventional Valve Unloading (Stepwise Control): This method is particularly noteworthy for its precision and reliability. It allows for gradual adjustment of the compressor’s capacity, ensuring optimal performance under varying operational demands.

OEM-Quality Standards

At FEROZ TECH International, our state-of-the-art CNC equipment and deep engineering expertise converge to ensure each compressor part we craft meets OEM-quality standards. We don’t just match the quality expectations — we exceed them, offering 100% compatibility with both OEM and aftermarket products. Our in-house injection molding process yields stress-free components, guaranteeing enhanced durability and prolonged service life.

Moreover, our metallic plates are not only precision-cut but also engineered to withstand the toughest conditions, boasting exceptional durability and resistance to wear and tear. This uncompromising approach to quality, combined with our fervent dedication to leading the industry in innovation and customer satisfaction, sets FEROZ TECH International apart from the competition as the go-to source for reliable compressor parts.