Industrial

Dust & Debris

Vacuum Cleaner

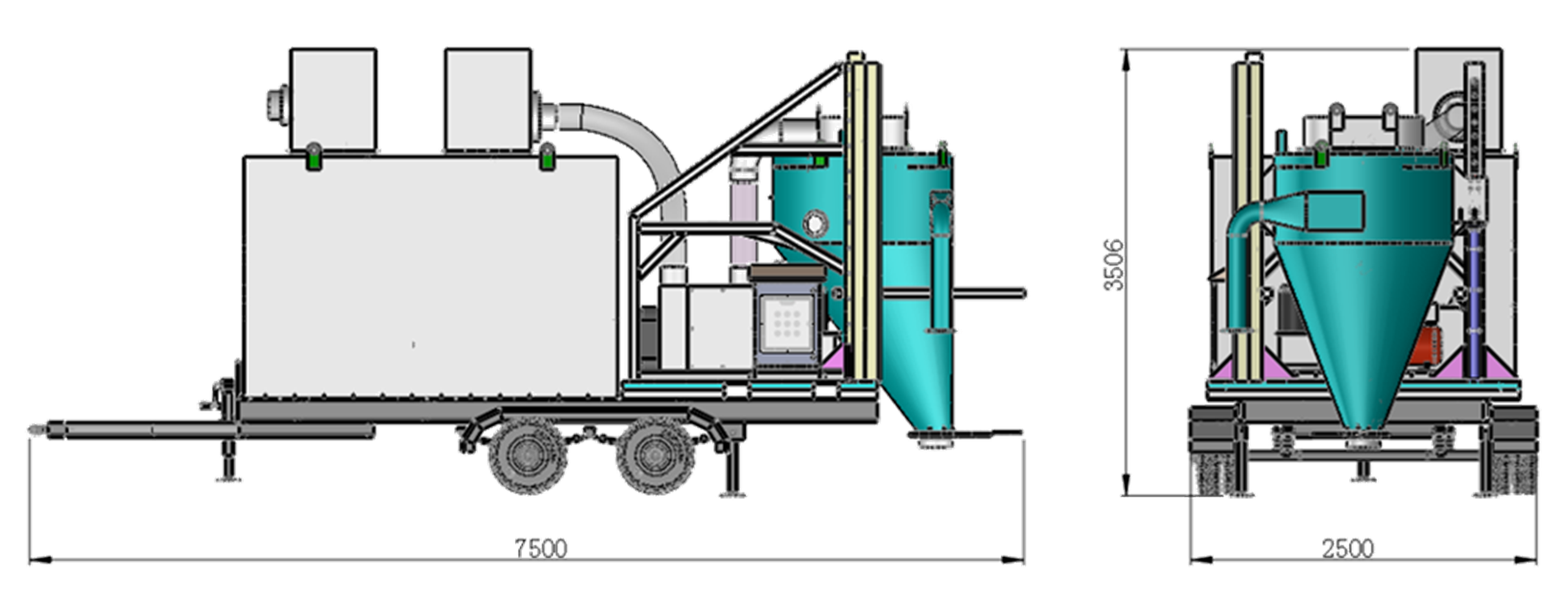

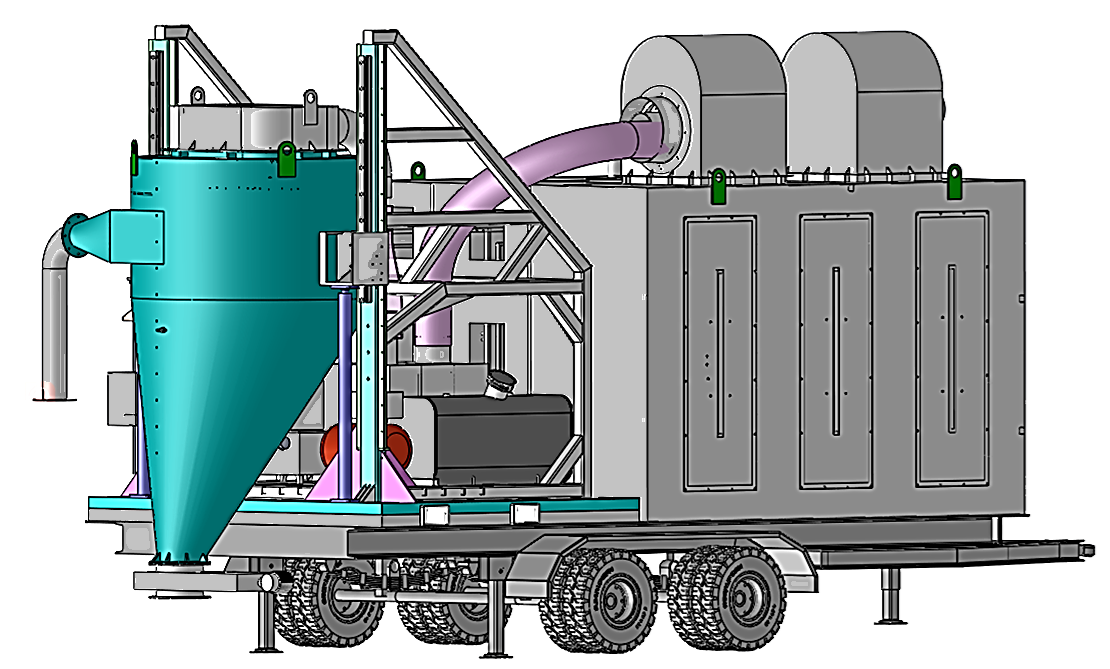

Compact, high-performance vacuum unit for collecting and transporting dry bulk materials – sand, shot, gravel, stones, earth, sludge, scale, all kinds of dust particles and hazardous waste (for example, asbestos).

VACUUM CLEANER

The ultra-compact design of the FT-IVC-03 is designed to solve a wide range of applications with the need for frequent movements (field service teams, cleaning companies, cleaning driveways). An ideal solution for cleaning departments and emergency crews whose task is to arrive on site in a timely manner and carry out cleaning as quickly as possible.

POWER

96 kW diesel or 75 kW electric vacuum pump drive. Suction capacity at a distance of 10 m (fresh cement) up to 24 tons/hour.

BIG BAGS

Dust-free unloading of material into BigBags or unloading into an open container. The filled 800L collection container is hydraulically lifted vertically to a height sufficient to accommodate a BigBag or open container underneath.

Managing Industrial Dust and Debris

Dust and ore spillage are pervasive issues in industrial environments, often leading to significant operational and safety challenges. In factories, power plants, and processing facilities, bulk materials such as coal, minerals, and other fine particulates are commonly handled or processed. These materials invariably generate dust that can accumulate in hard-to-reach areas of the machinery and the surrounding environment. Over time, these accumulations not only degrade machinery efficiency but also pose serious health risks to workers through respiratory exposure. Additionally, the build-up of such materials can create fire hazards, particularly in industries dealing with combustible dusts. Regular cleaning and maintenance are crucial yet challenging due to the often inaccessible nature of these spill sites. Industrial vacuum systems are therefore essential, enabling effective removal of these hazardous materials from even the most difficult-to-reach areas, thus maintaining operational safety and compliance with health regulations. This necessitates robust solutions and systems that can handle the rigors of industrial waste management while ensuring that all areas, no matter how inaccessible, remain free from hazardous dust and debris.

Working at -52 °C

Explosion-Proof

Constant Suction Power

Fill Sensor

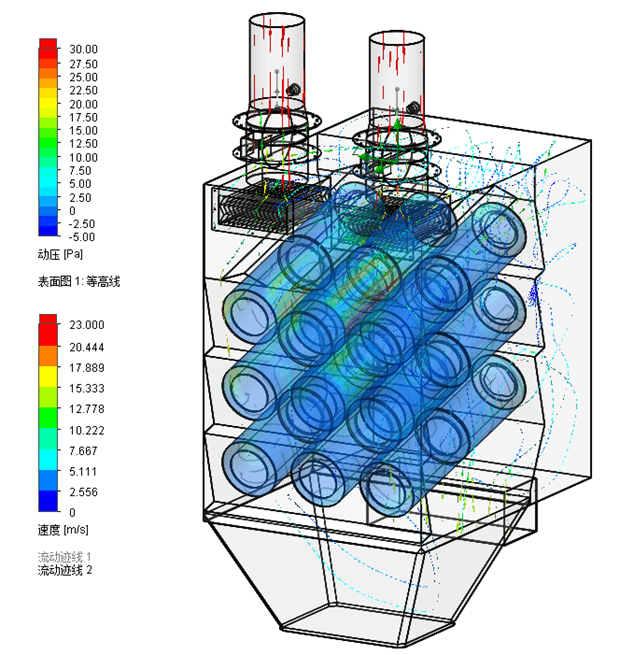

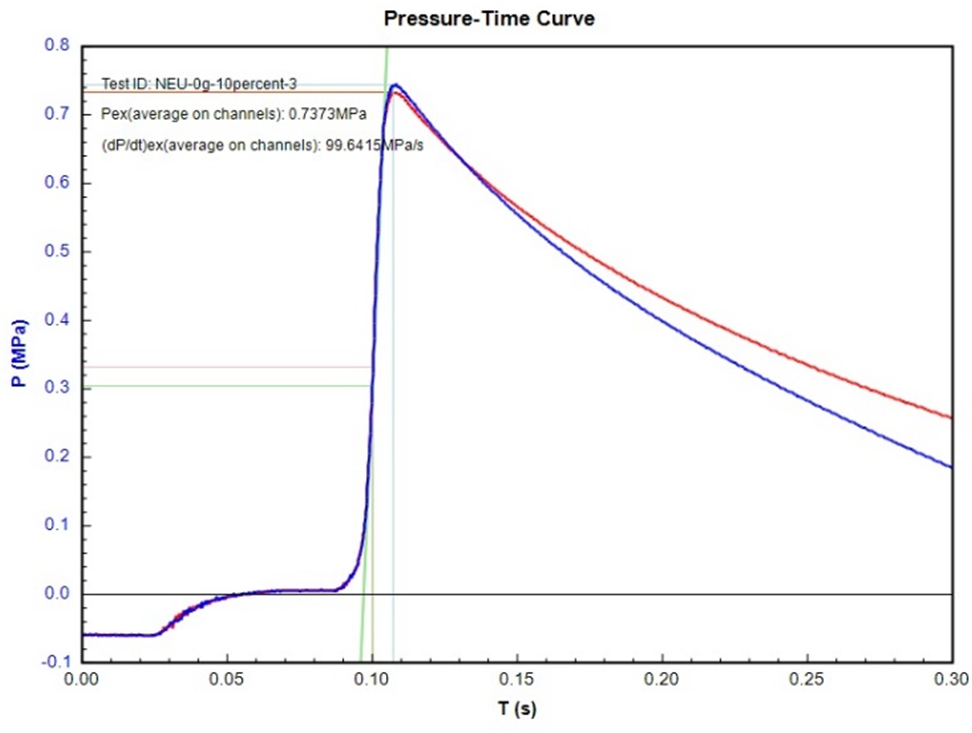

Advanced Technologies: Flow Modeling and Dust Analysis

With powerful simulation technology, FEROZ TECH International has the competence to predict the performance and results of potential solutions and thus propose the optimal solution to suit a client’s unique production process.

The Best in Technology

Filtration efficiency:

- The filtration efficiency of 0.3 micron particles is more than 99.97%.

- First stage filter (cyclone)

99% for 10 µm particles. - Second stage filter (cartridge filter)

99% for particles 0.3 µm in size. - Third stage filter (HEPA filter unit)

99.5% for 0.3 µm particles